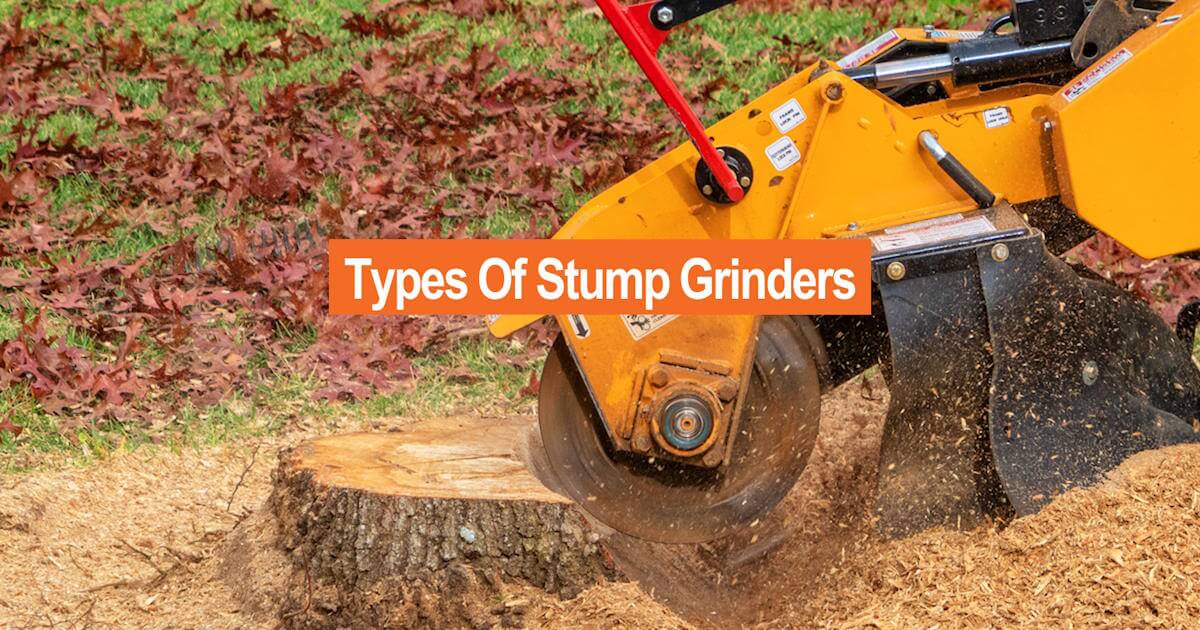

There are several variations of stump grinders, most notably in how they look (their design) and how they operate, but the general principle of grinding away the stump using a rotating cutting wheel remains a standard feature on all stump grinding equipment.

The biggest difference is how the stump cutter is positioned near to the stump. The machine may be a standalone unit, attached to a vehicle (such as a tractor or skid steer) or attached to an excavator.

The cutting wheel can either use sharp teeth or blades to cut (or grind) away at the stump as the cutting wheel is lowered onto it.

Choosing the correct stump cutter for the job will depend on the accessibility of the job site and the scale of the project.

We investigate the different types of stump cutters and where they are commonly used.

Walk-Behind Stump Grinders

As the name suggests, these stump grinders are operated by “walking behind” them. They tend to be compact, lightweight and portable machines as they need to be moved by the operators.

They typically have a long frame supported by wheels. The engine is mounted near the middle of the frame, with a handle at one end of the frame for controlling the grinder. At the opposite end sits the cutting wheel. The spinning cutting wheel is powered by a belt connected to the (petrol or diesel) engine.

This compact configuration makes them perfect for smaller residential projects or areas with limited access. They are especially good for grinding stumps close to buildings or fences as they are easier to control.

These are best suited to smaller trunk sizes and are not designed to tackle forest clearings or large-scale projects.

As they can often be transported in the back of a van or pick-up truck, they tend to be available from hire companies for short-term use.

Self-Propelled Stump Grinders

These grinders are similar to walk-behind models but come equipped with their own power source to move them about.

Self-propelled cutters are available in wheeled and tracked versions (see photo), with many manufacturers offering remote-control versions.

As they have power to move about, you will find larger models are available which can handle bigger stumps. The powered wheels allow operators to manoeuvre them into locations which they otherwise couldn’t get to by manually pushing the machine.

Be warned, they are not fast-moving bits of kit; top speeds are usually restricted to around 2-3mph. Specific models can use the braking system to allow them to climb stairs.

Tracked Stump Grinders

Track-mounted stump grinders have the main cutting machinery located on tracks rather than wheels. This improves the mobility and stability of the equipment and allows the tracked machine to reach locations that walk-behind, towable grinders etc, can’t get to.

One added benefit of tracked cutters is the broad footprint gives additional stability when grinding on uneven surfaces, slopes or areas of soft ground. They also offer better traction and have less impact on the surface compared to wheeled models.

This makes them ideal for off-road sites.

Common uses for stump grinders on tracks include forestry, right-of-way clearing, park maintenance and land clearing.

Popular tracked models included the Vermeer SC70TX and the Predator 56RX. You can read more information in our top stump grinding brands guide.

As tracked models tend to be more expensive than wheeled versions, you will often notice that “remote controlled” variants are available.

Stump Grinders For Excavators

More often than not, forestry workers will use excavators to help fell trees and clear forests. One crucial attachment is the stump grinder.

Excavator-mounted stump grinders are powerful bits of kit that use the existing excavator hydraulic system for operation.

As the grinder is attached to the digger arm, it allows the operator to manoeuvre the grinder and reach stumps in different locations. With the versatility of tracked excavators, it extends the areas that other cutter types might be unable to reach.

Stump grinder attachments for excavators are typically rated in a “per tonne” range, such as 1.5 – 4.5t or 7 – 15t, where the size is matched to the excavator weight.

These types of cutters are typically used in heavy-duty commercial applications and can efficiently deal with large stumps.

Stump Grinder For Tractors

Power take-off stump grinders (PTO) are generally fitted to a tractor’s 3-point hitch and are powered by the take-off system.

Assuming the tractor is compatible and has sufficient horsepower to turn the cutting wheel, these cutters are ideal for agricultural locations and other commercial areas.

While some manufacturers have produced grinders for compact tractors with as little as 15hp, the fact that these cutters are mounted on the rear of the tractor means access to tight spaces or residential gardens is limited.

Skid Steer Stump Grinder Attachment

Specially adapted skid steer / Bobcat vehicles are often used in forest environments by arborists and forestry workers. Skid steer stump cutter attachments connect to the steers’ hydraulic arms via couplers or mounting plates.

The cutter is powered through hoses connected to the skid’s existing hydraulic system. Skid steers are renowned for their manoeuvrability, which means they can easily position the cutter above the stump using the lifting arms.

During the grinding process, the operator can quickly move the cutter across the stump and apply downward pressure until the stump is cut to the desired level.

If the operator already has access to a skid steer, this is seen as a more affordable option when compared to buying a standalone tracked or wheeled cutter.

Tow-Behind Stump Grinders

These variants are attached to the back of a vehicle using a tow hitch and are towed to the job site. They usually are much larger and more powerful than walk-behind or self-propelled models – making them more suitable for heavy-duty projects.

By the nature of how they are moved about, this limits the locations where these types of grinders can access – as they can only go where the tow vehicle can reach.

Popular tow behind models sold worldwide include the Carlton 7500 series and the Rayco RG series.

One obvious benefit of a towable stump grinder is they do not need a trailer to carry the machine; this saves time (and expense) of loading and unloading the equipment.

Tow behind stump cutters can include their own brakes, lights, indicators, brake lights and number plate boards to make them legal for towing on UK roads.

Stump Grinder Attachment For Chainsaws

For smaller projects, such as removing one or two small stumps in a residential garden, bolting on a stump grinder attachment to a chainsaw can deal with this.

The stump grinder attaches to the chainsaw bar and typically consists of a circular metal disk with carbide-cutting teeth around the perimeter.

This type of rig is a much cheaper and more portable stump grinding option when compared to large standalone grinders. It also can offer access to tight spaces where bigger equipment can’t go.

However, it is not really practical for large stump removal jobs – as it requires more physical effort from the operator, as they need to move the cutting disc across the stump and keep pushing downwards to eat into the stump. It also comes with higher safety risks.

Financing Stump Grinders

Shopping for a stump grinder can be a significant investment; that’s why it’s essential to consider the different types of finance options available to secure the suitable machine for your needs.

At Evangate FS, we understand that arranging finance can be overwhelming, which is why we recommend working with our experienced forestry finance brokers to secure the best financing deal you can.

We have access to over 100 lenders, which means we can offer you a wider range of finance options than you might find on your own.

We also can save you time by processing the application for you. And possibly the most important reason for speaking with us, is that we can often get better finance rates with more attractive terms.

Our team also have a deeper understanding of the lending and risk assessment criteria of the lenders. We will present your application in the best possible light to increase the chances of quick approval – meaning you can get your hands on a stump grinder sooner.